How to build mini press

by Plastmakers

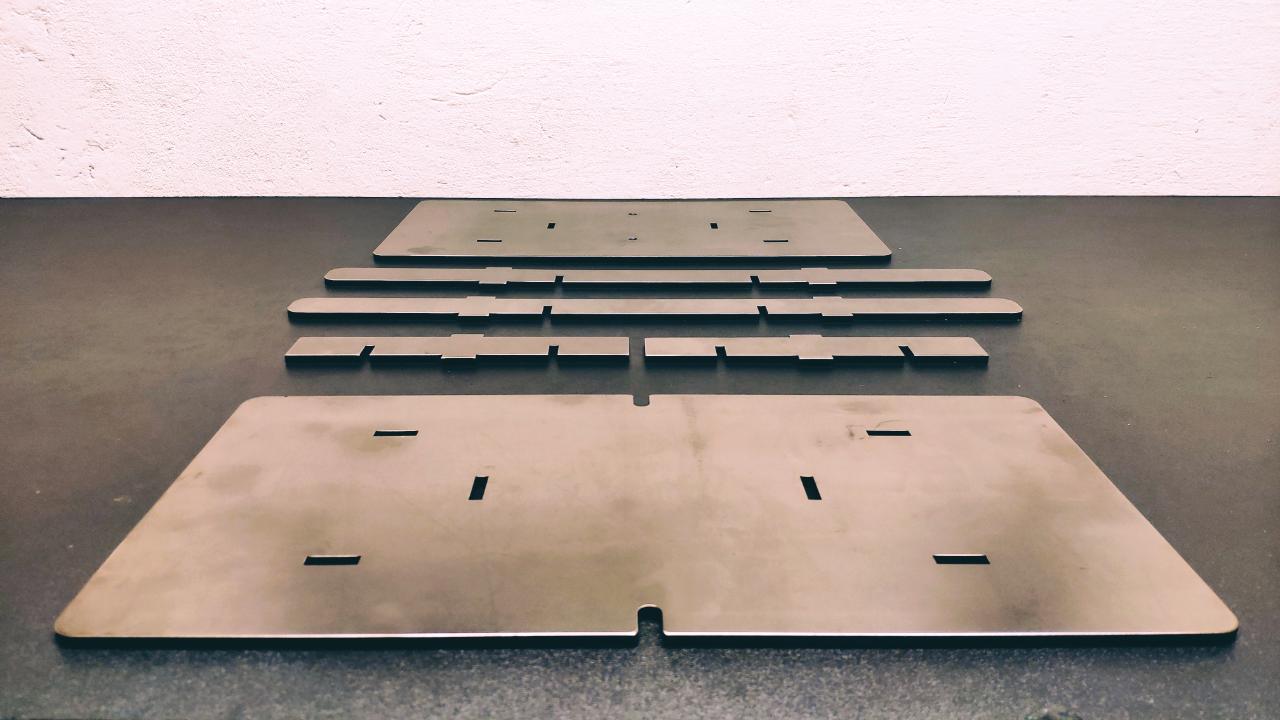

Tutorial how to build mini press for compression moulding.

For making this simple machine you need welding machine, access to laser cutting machine, drilling machine and basic assembly skills.

—

Attachments

Resources

3D Files

- 3D Step File: /files/03 Mini press/STP/c-01-2001-01.stp - Preview

- 3D Step File: /files/03 Mini press/STP/c-01-2003-01.stp - Preview

- 3D Step File: /files/03 Mini press/STP/c-01-2005-01.stp - Preview

- 3D Step File: /files/03 Mini press/STP/c-01-3000-01.stp - Preview

- 3D Step File: /files/03 Mini press/STP/c-01-3001-01.stp - Preview

- 3D Step File: /files/03 Mini press/STP/c-01-3002-01.stp - Preview

- 3D Step File: /files/03 Mini press/STP/c-01-3003-01.stp - Preview

- 3D Step File: /files/03 Mini press/STP/c-01-3004-01.stp - Preview

Step 1 - Video tutorial

All steps are mentioned in video tutorial.

Direct link to open source blueprints and CAD files are here:

https://drive.google.com/drive/folders/1mnhn5dmxhTUJN2FP2GhcQiJN7mrv-iHk?usp=sharing

Direct link to open source blueprints and CAD files are here:

https://drive.google.com/drive/folders/1mnhn5dmxhTUJN2FP2GhcQiJN7mrv-iHk?usp=sharing

Step 2 - What can you make with press?

With this standard size frame it is possible to press sheets with area 37x37cm.

Max. recommended mould height is 80mm

I have already produced:

- sheets 37x37cm, thickness 3, 5, 20mm

- coasters

- clock

- clipboard

- sheets which was latter used for CNC cutting - design of lamp, animal models.

Max. recommended mould height is 80mm

I have already produced:

- sheets 37x37cm, thickness 3, 5, 20mm

- coasters

- clock

- clipboard

- sheets which was latter used for CNC cutting - design of lamp, animal models.

Step 3 - Is it possible to buy it? Yes

Full machine:

https://bazar.preciousplastic.com/machines/sheetpress/sheet-press-kits/mini-press/

Laser cutted parts for pressing plates:

https://bazar.preciousplastic.com/machines/sheetpress/sheet-press-parts/laser-cutted-parts-for-mini-press/

https://bazar.preciousplastic.com/machines/sheetpress/sheet-press-kits/mini-press/

Laser cutted parts for pressing plates:

https://bazar.preciousplastic.com/machines/sheetpress/sheet-press-parts/laser-cutted-parts-for-mini-press/

Step 4 - More information

Next upgrades and tips for compression moulding you can find on Youtube, or Instagram:

https://linktr.ee/plastmakers

I hope it can help you with plastic recycling.

Tom

https://linktr.ee/plastmakers

I hope it can help you with plastic recycling.

Tom

—

—

—

Comments