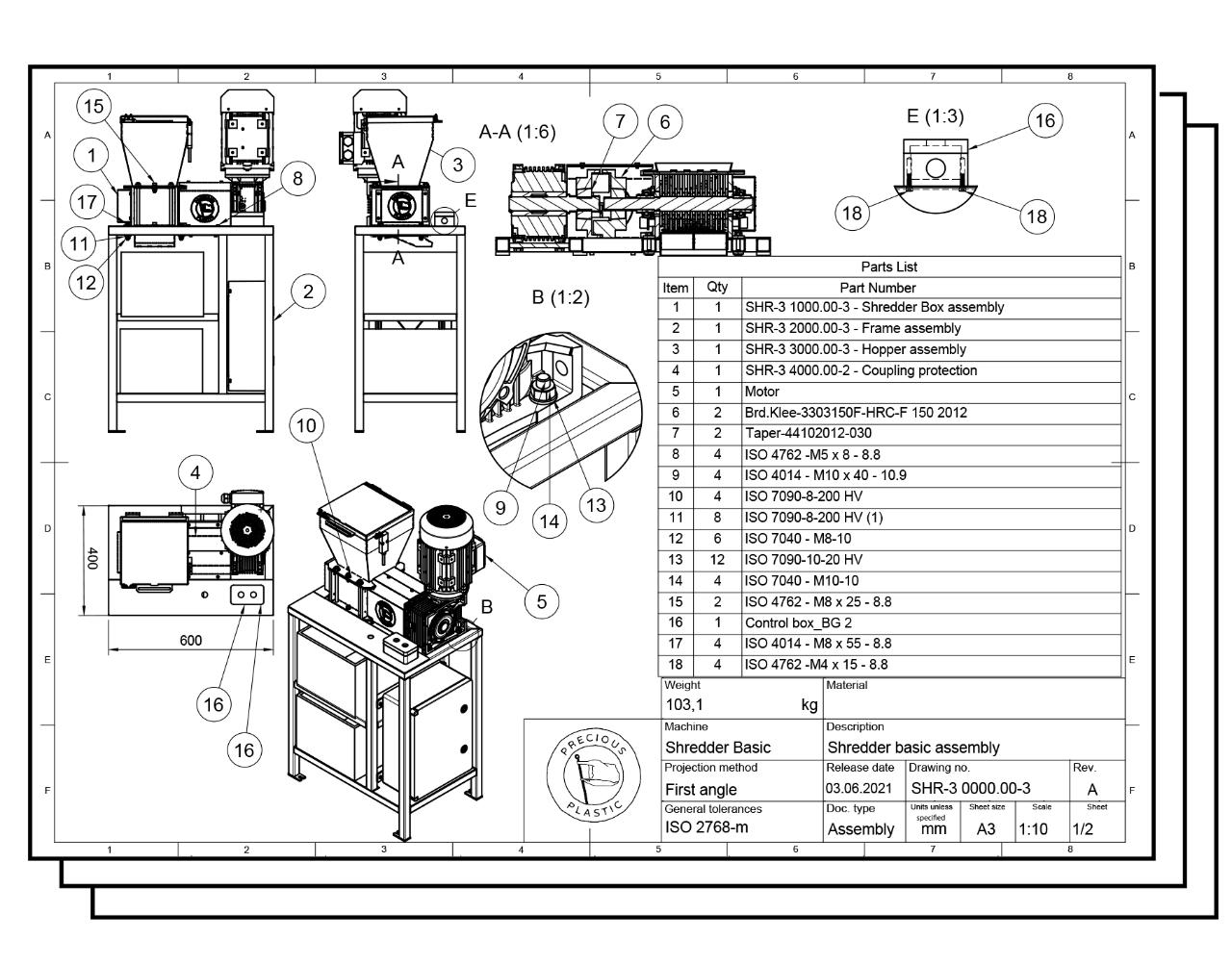

SHR - 3.3

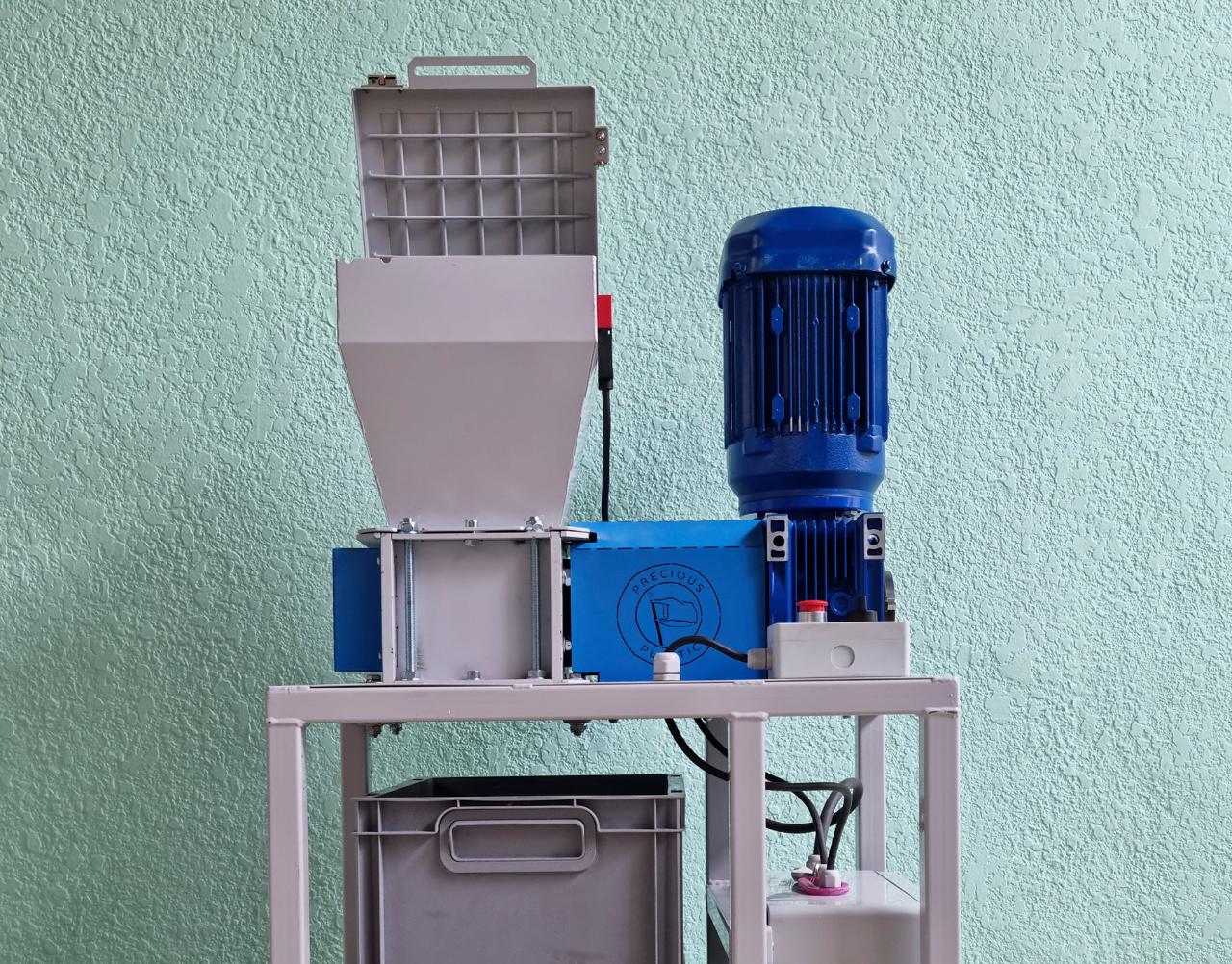

Shredding is the first step of processing the precious plastic that you collected. It will break apart it into flakes and then they will be ready to be processed with the other machines to create new precious products . The main diffference between the Shredder Basic and PRO it's their shredding capacity, the SHRPRO can shred up to 50 kg/h and the SHR Basic up to 15 kg/h.

This latest version of the Shredder Basic (3.3) solves 2 main problems: Safety and transportability. How? By following the CE safety requirements (European standards) and designing it to be as compact as possible.

—

Attachments

Resources

3D Files

- 3D Step File: /files/cad/SHR-3 0000.00-3.step - Preview

Step 1 - Download

First off, click on the Download button above to check out all the files for this machine!

In this folder you will find:

- 3D CAD (.step and .f3d)

- Lasercut files (.dxf)

- Blueprints (.pdf)

- Schematics

- BOM

... and more :)

You can see a preview of all the files (in case you are just curious 👀) and you'll also be able to download them for manufacturing 🔧

In this folder you will find:

- 3D CAD (.step and .f3d)

- Lasercut files (.dxf)

- Blueprints (.pdf)

- Schematics

- BOM

... and more :)

You can see a preview of all the files (in case you are just curious 👀) and you'll also be able to download them for manufacturing 🔧

Step 2 - Build

There are a few required skills and machinery you'll need to have if you’re building this machine yourself, or for the machine builder if you are asking someone else to build it for you:

- General metalworking (cutting, drilling)

- Welding

- Turning (machining on a lathe)

- Laser cutting

- General electrical work (wiring safety switch, temperature controllers…)

- Motor electrical work (wiring motor, contactor, overload protection…)

- Programming (VFD if you use one)

- Advanced assembly work (require specific tools, measurement instruments and tolerances knowledge to align and assemble)

- Painting

⚙️ Machinery / specific tools needed:

- Grinder, chop saw, MIG/MAG or TIG, drill press

- Lathe

- Laser cutting (this can easily be subcontracted around the world)

- Torque wrench and bearing mounting tool

- General metalworking (cutting, drilling)

- Welding

- Turning (machining on a lathe)

- Laser cutting

- General electrical work (wiring safety switch, temperature controllers…)

- Motor electrical work (wiring motor, contactor, overload protection…)

- Programming (VFD if you use one)

- Advanced assembly work (require specific tools, measurement instruments and tolerances knowledge to align and assemble)

- Painting

⚙️ Machinery / specific tools needed:

- Grinder, chop saw, MIG/MAG or TIG, drill press

- Lathe

- Laser cutting (this can easily be subcontracted around the world)

- Torque wrench and bearing mounting tool

Step 3 - Run, Create and Sell :)

READY TO SHRED?

To run and maintain this machine properly and safely, make sure to have a look at its MANUAL:

👉 https://workbench.grabcad.com/workbench/projects/gcUbMRKUCFx7X5PxSFsPZs9Em9RwRsNaz30AJEp-hmriQl#/space/gc5PUkFy1QZe-n49PeCWmCLojw8Y3ieBpX2S96s8tcRKS-/link/3346603

Buy and sell on the Bazar!

On the Precious Plastic Bazar, you can buy machine parts to maintain your machine, or sell your machine or the shredded plastic you're producing with it - or much more!

👉 bazar.preciousplastic.com

Happy shredding! 🤗

To run and maintain this machine properly and safely, make sure to have a look at its MANUAL:

👉 https://workbench.grabcad.com/workbench/projects/gcUbMRKUCFx7X5PxSFsPZs9Em9RwRsNaz30AJEp-hmriQl#/space/gc5PUkFy1QZe-n49PeCWmCLojw8Y3ieBpX2S96s8tcRKS-/link/3346603

Buy and sell on the Bazar!

On the Precious Plastic Bazar, you can buy machine parts to maintain your machine, or sell your machine or the shredded plastic you're producing with it - or much more!

👉 bazar.preciousplastic.com

Happy shredding! 🤗

—

—

—

-18066e186ac.jpg)

Comments