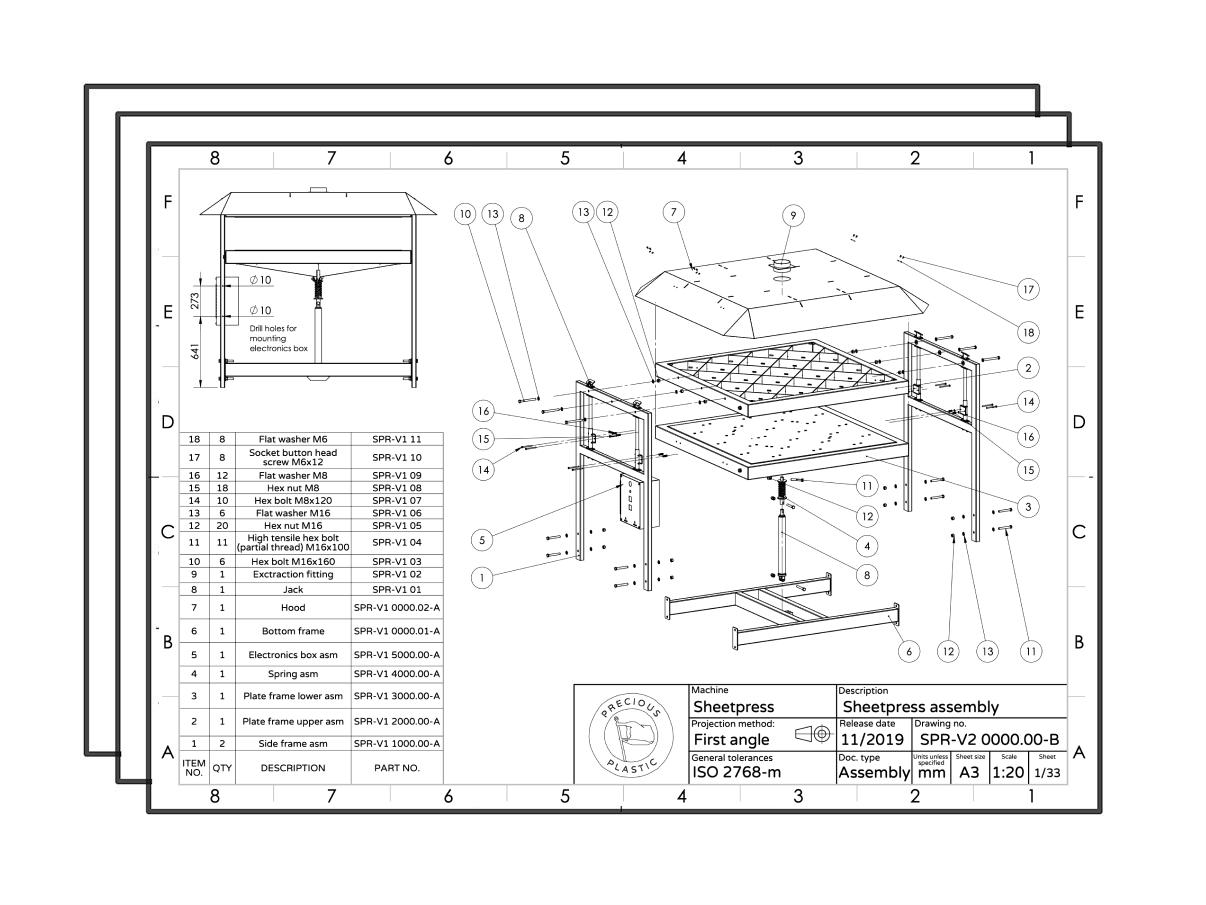

1.5m Sheetpress System - Designed for Disassembly

Complete set of blueprints, CAD files and instructions on how to build this upscaled sheetpress system.

-56% larger pressing surface

-Designed for easy disassembly

-Improved electronics

—

Attachments

Resources

Step 1 - Download

Here's a link to the build folder:

https://drive.google.com/drive/u/1/folders/19glmxFnX6oH5BvBAc8NxFk5f-9YG9HNb

If you're setting up a sheetpress workspace, you should still download our sheetpress workspace starterkit from our academy. Just use this build folder instead of the build folder in the main starterkit.

And here's a link to our original build video. The design is slightly different but the steps are the same:

https://www.youtube.com/watch?v=j3OctDe3xVk

https://drive.google.com/drive/u/1/folders/19glmxFnX6oH5BvBAc8NxFk5f-9YG9HNb

If you're setting up a sheetpress workspace, you should still download our sheetpress workspace starterkit from our academy. Just use this build folder instead of the build folder in the main starterkit.

And here's a link to our original build video. The design is slightly different but the steps are the same:

https://www.youtube.com/watch?v=j3OctDe3xVk

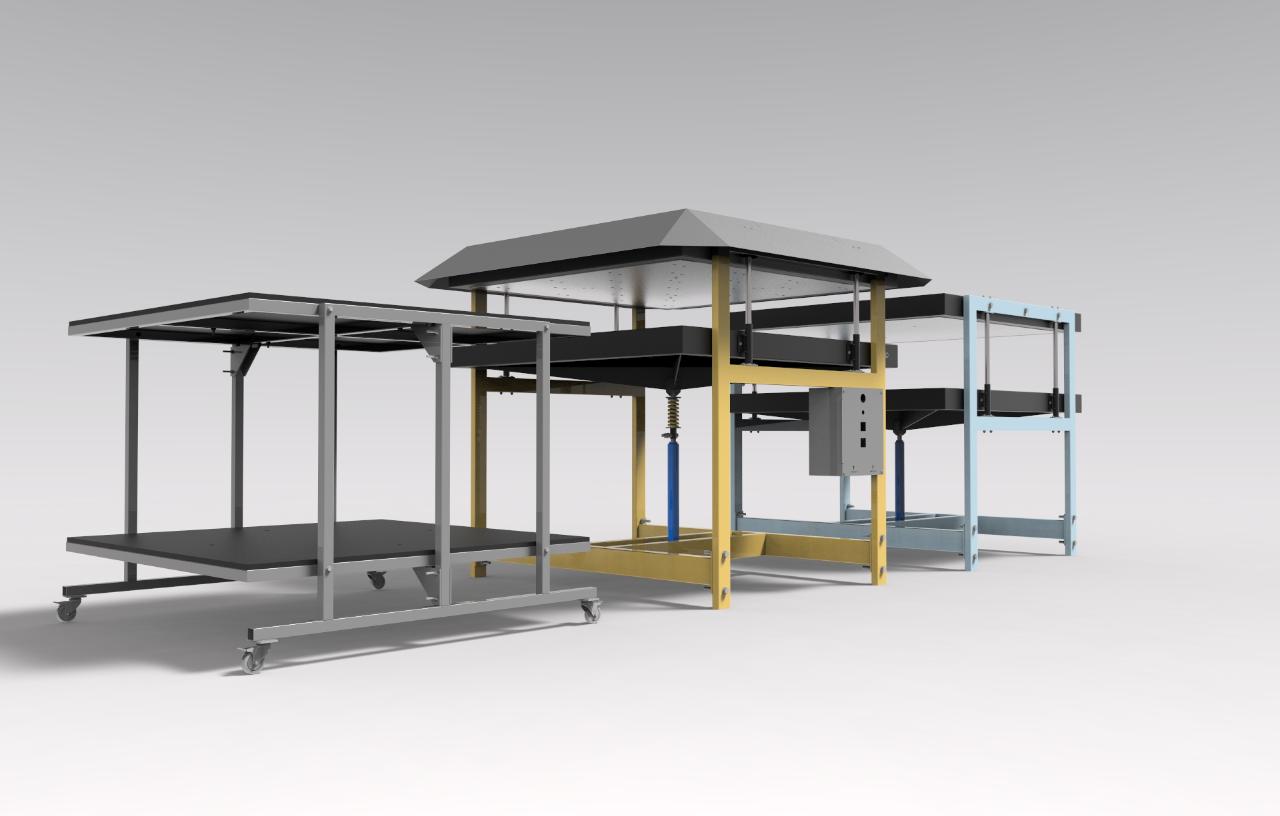

Step 2 - Bigger Press = Bigger Sheets

This system has been upscaled to a 1.5x1.5m pressing surface. This allows you to easily make plastic sheets at the standard 1.2x1.2m size and even a bit bigger.

This is a 56% increase in capacity so you'll be able to recycle plastic at more than 50% the rate as the V4 press.

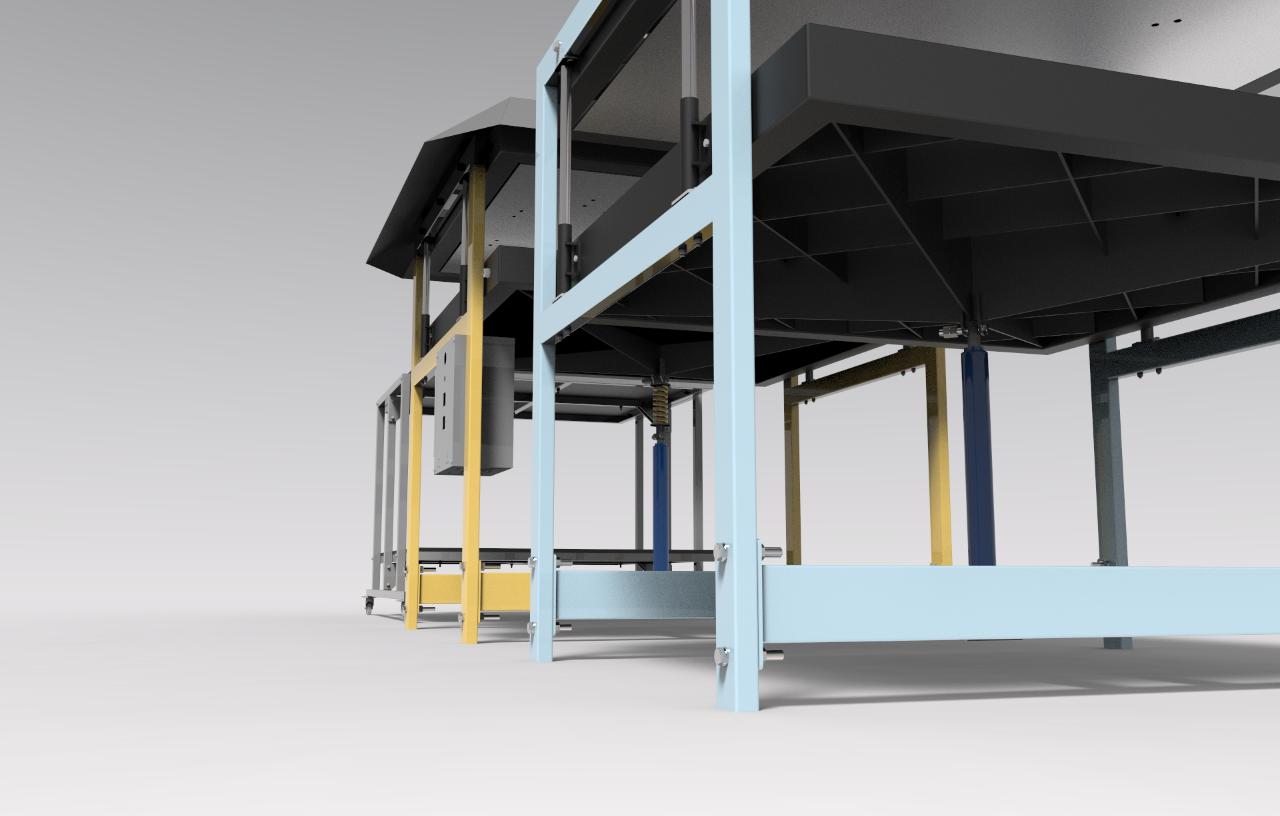

Note: The press requires 1500x3000 sheets of steel and aluminium to build. It's also quite a bit heavier, so it's no longer possible to handle the parts in this machine without the assistance of a hoist or similar lifting device.

This is a 56% increase in capacity so you'll be able to recycle plastic at more than 50% the rate as the V4 press.

Note: The press requires 1500x3000 sheets of steel and aluminium to build. It's also quite a bit heavier, so it's no longer possible to handle the parts in this machine without the assistance of a hoist or similar lifting device.

Step 3 - Designed for Disassembly

The whole system has been designed to be disassembled for easy packing and transportation. It now fits through a standard door when disassembled.

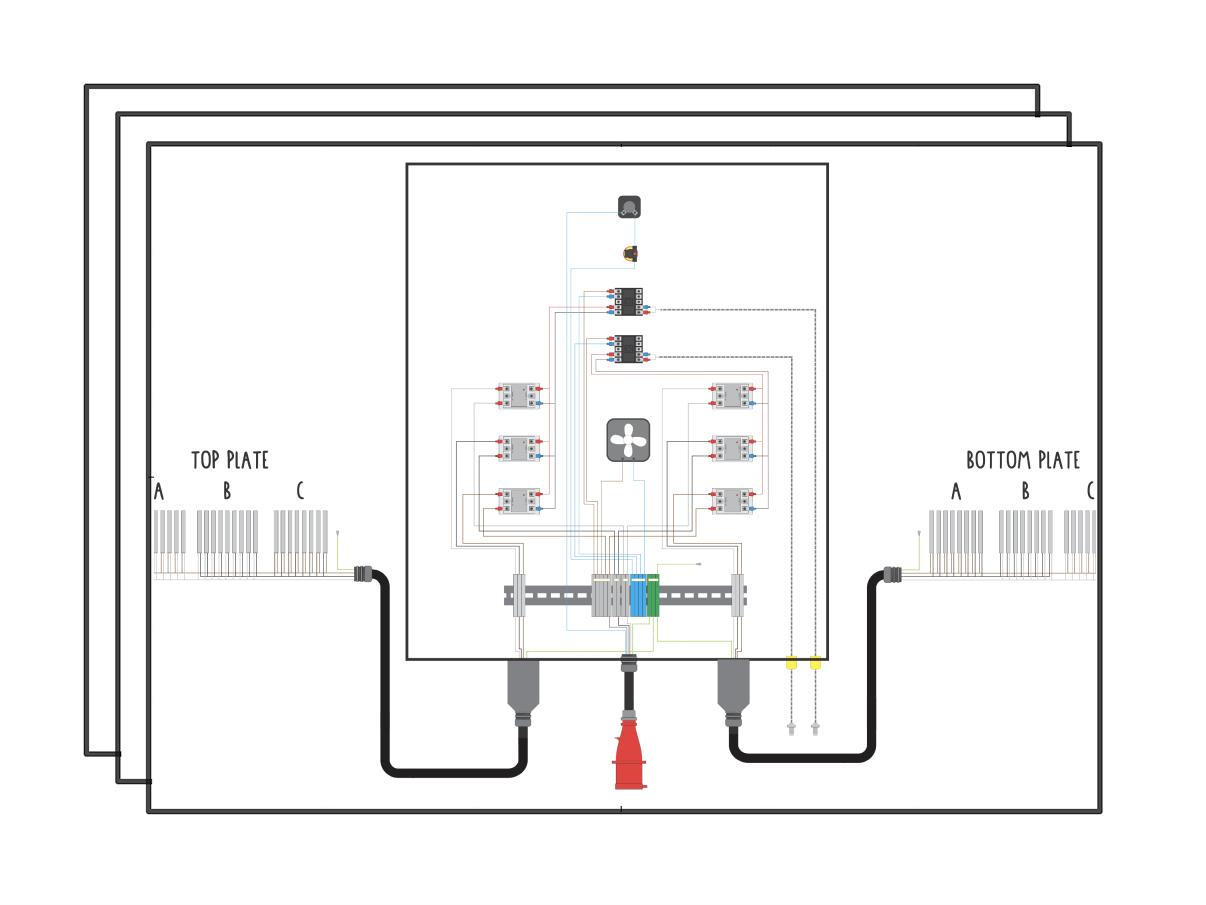

The electronics box can also be unplugged and dismounted for transportation.

The electronics box can also be unplugged and dismounted for transportation.

Step 4 - Improved Electronics

We've made some changes to the electrical system to better suit the increased power requirements of this larger machine.

Step 5 - Build it, hack it, share it!

If you have any other ideas, improvements or hacks for this machine - make sure to share them with the community.

You can do this through a how-to, discord or instagram!

Have fun building :)

You can do this through a how-to, discord or instagram!

Have fun building :)

—

—

—

Comments