PET MINI - Recycled Electric Skate

by VIVA Lab - Precious Plastic

PET MINI Skateboard is a Open Source, Recycled Electric Skateboard for urban transportation. With the goal to end stressful commutes and boost your door-to-door speed with the perfect last mile recycled vehicle.

If you have any questions or would like to collaborate with the community from Portugal reach out to us!

<a href="https://www.vivalabporto.com/">https://www.vivalabporto.com/</a>

<a href="https://www.makerisland.io/">https://www.makerisland.io/</a>

—

Attachments

Resources

Step 1 - Story

PET MINI (Personal Electric Transport) was developed based on the growing importance of creating participatory approaches to design.

By using the potential of Open Design we can easily prototype and distribute design's at a global scale while promoting local manufacturing and problem solving.

We were grateful to get the recycled plastic PP sheet's from Precious Plastic HQ for the first prototypes, they were machined by a CNC router to obtain the skateboard deck. Mechanical parts were 3D printed to speed up prototyping phase, as the parts were manufactured at a local Fab Lab, VIVALab, so it can easily be replicated at any of the 2,000 Fab Lab's from the global network.

By using the potential of Open Design we can easily prototype and distribute design's at a global scale while promoting local manufacturing and problem solving.

We were grateful to get the recycled plastic PP sheet's from Precious Plastic HQ for the first prototypes, they were machined by a CNC router to obtain the skateboard deck. Mechanical parts were 3D printed to speed up prototyping phase, as the parts were manufactured at a local Fab Lab, VIVALab, so it can easily be replicated at any of the 2,000 Fab Lab's from the global network.

Step 2 - Bill Of Materials (BOM)

There is a whole world around DIY electric skateboards, different specs and consequently several different parts you can choose from. The parts we used allow a top speed of 35 km/h and a range of 36km:

1x 10s BESTECH bms 60a Battery Pack 12s2p (10s3p)

1x BUNDLE HTD 5M 53 teeth Belt 265mm

1x Electric Skateboard Speed Controller Open Source VESC

1x Eskating PRO motors 6374 190Kv

2x Caliber II Trucks 50° 10″

4x Kegel 80mm Wheels

8x ABEC 608

1x 2.4GHz remote

1x 16T Motor Pulley (8mm or 10mm)

1x 3D printed Wheel gear Pulley and Motor Mount

1x Skateboard Hardware Set - 1"

2x 1/2" Rubber Riser Pads

1x 1m of 1mm Rubber Window insulation

1x 10s BESTECH bms 60a Battery Pack 12s2p (10s3p)

1x BUNDLE HTD 5M 53 teeth Belt 265mm

1x Electric Skateboard Speed Controller Open Source VESC

1x Eskating PRO motors 6374 190Kv

2x Caliber II Trucks 50° 10″

4x Kegel 80mm Wheels

8x ABEC 608

1x 2.4GHz remote

1x 16T Motor Pulley (8mm or 10mm)

1x 3D printed Wheel gear Pulley and Motor Mount

1x Skateboard Hardware Set - 1"

2x 1/2" Rubber Riser Pads

1x 1m of 1mm Rubber Window insulation

Step 3 - Sheet Press, 3D Printing & CNC

Start by making your 20mm sheet using the sheetpress.

Related links:

How to make sheets 👉 tiny.cc/run-the-sheetpress

Find sheets on the Bazar👉 bazar.preciousplastic.com

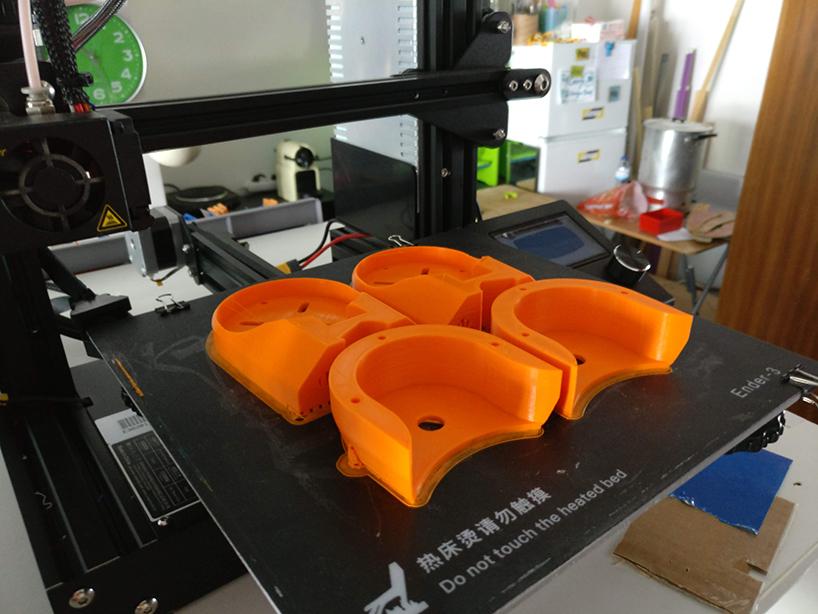

3D print the Armadillo Electronic case, Wheel gear Pulley and Motor Mount

3D printing Parameters:

👉Armadillo Case:

PLA

25% - 45% Infill

0.3mm layer hight

👉 Motor Mount:

ABS

<45% Infill

0.2mm layer hight

👉Wheel Gear Pulley:

PC-ABS or Carbon Fiber

<45% Infill

0.2mm layer hight

3D CNC Milling 20mm Plastic Sheet using the 3d model of the deck parameters will depend on the available CNC at your local Fab Lab or Makerspace.

Related links:

How to make sheets 👉 tiny.cc/run-the-sheetpress

Find sheets on the Bazar👉 bazar.preciousplastic.com

3D print the Armadillo Electronic case, Wheel gear Pulley and Motor Mount

3D printing Parameters:

👉Armadillo Case:

PLA

25% - 45% Infill

0.3mm layer hight

👉 Motor Mount:

ABS

<45% Infill

0.2mm layer hight

👉Wheel Gear Pulley:

PC-ABS or Carbon Fiber

<45% Infill

0.2mm layer hight

3D CNC Milling 20mm Plastic Sheet using the 3d model of the deck parameters will depend on the available CNC at your local Fab Lab or Makerspace.

Step 4 - Electronics

We share with you a comprehensive tutorial to program your electronics and to assemble your electronics

👉Electronics Assembly: https://www.youtube.com/watch?v=W5kOgzW5Jmc&list=PLkqXGkAj77a4fVV9FmcT0fqr66eJbBoh0

👉Electronics Assembly: https://www.youtube.com/watch?v=W5kOgzW5Jmc&list=PLkqXGkAj77a4fVV9FmcT0fqr66eJbBoh0

Step 5 - Have Fun!!!

After Assembling all the different parts, programming your electronics and adding the rubber insulation to the Electronics case you are ready to test your e-skate.

Ride Safe and Have Fun! 🛹♻

If you have any questions or would like to collaborate with the community from Portugal reach out to us!

https://www.vivalabporto.com/

https://www.makerisland.io/

Share your results to:

@vivalabporto

@realpreciousplastic

#preciousplastic

#vivalabporto

Ride Safe and Have Fun! 🛹♻

If you have any questions or would like to collaborate with the community from Portugal reach out to us!

https://www.vivalabporto.com/

https://www.makerisland.io/

Share your results to:

@vivalabporto

@realpreciousplastic

#preciousplastic

#vivalabporto

—

—

—

Comments