Myriad Injector

Specification

| Standard | |

|---|---|

| Weight | 35 Kg |

| Package Dimensions | 130 x 30 x 55 cm |

| Plunger Diameter | 25 mm – 30 mm |

| Usable Barrel Length | Up to 45 cm |

| Supported Voltage | 220V / 110V |

| Input Flake Size | Small - Medium |

| Plastic Shot Size | Up to 300 gramm |

| Transmission | 1: 1.5 |

| Mold Interface | M20 thread / Cone Nozzle |

| Heatbands | 4 (250W) / Ceramic |

| Temperature Controller | 2 – Inkbird |

Authors

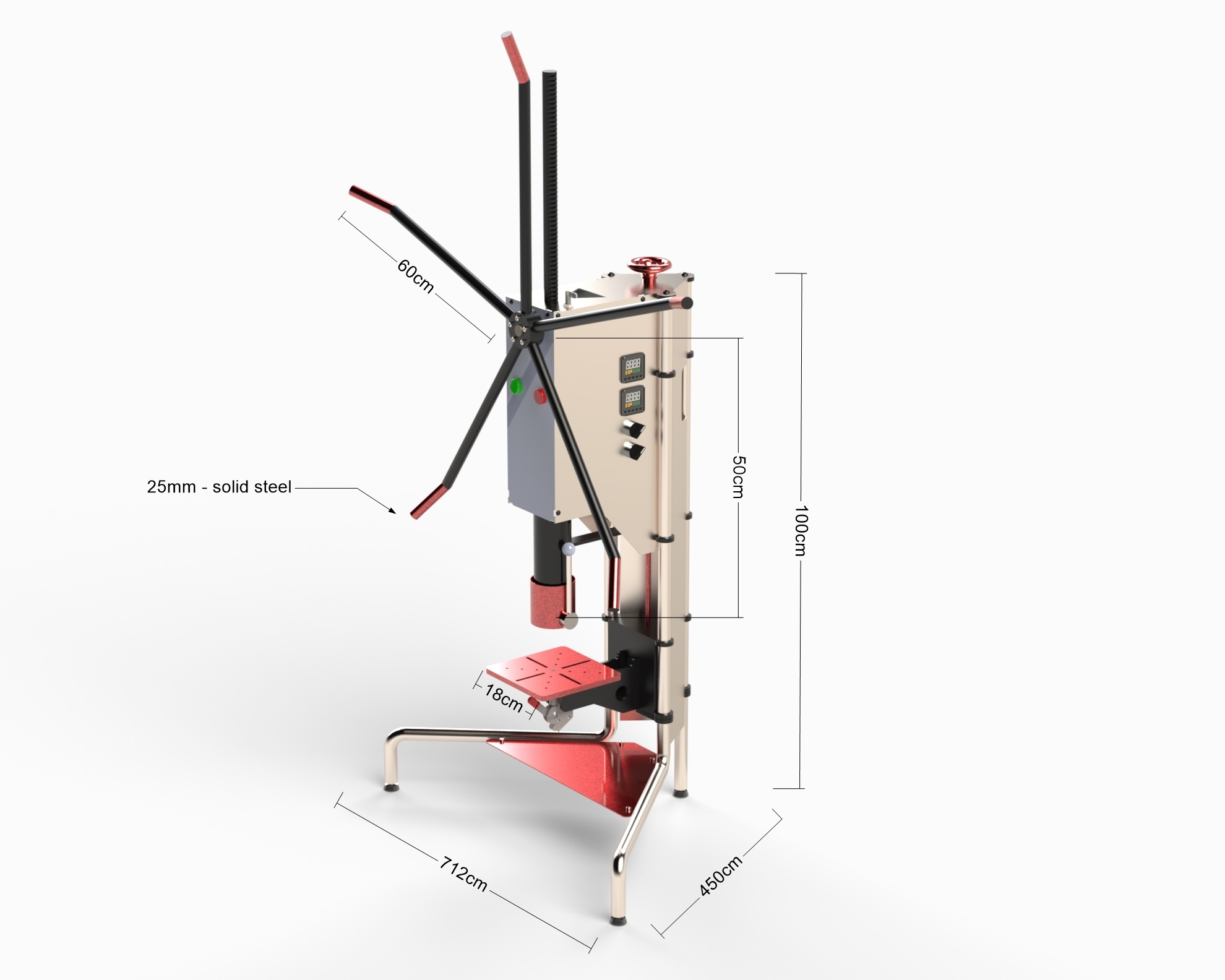

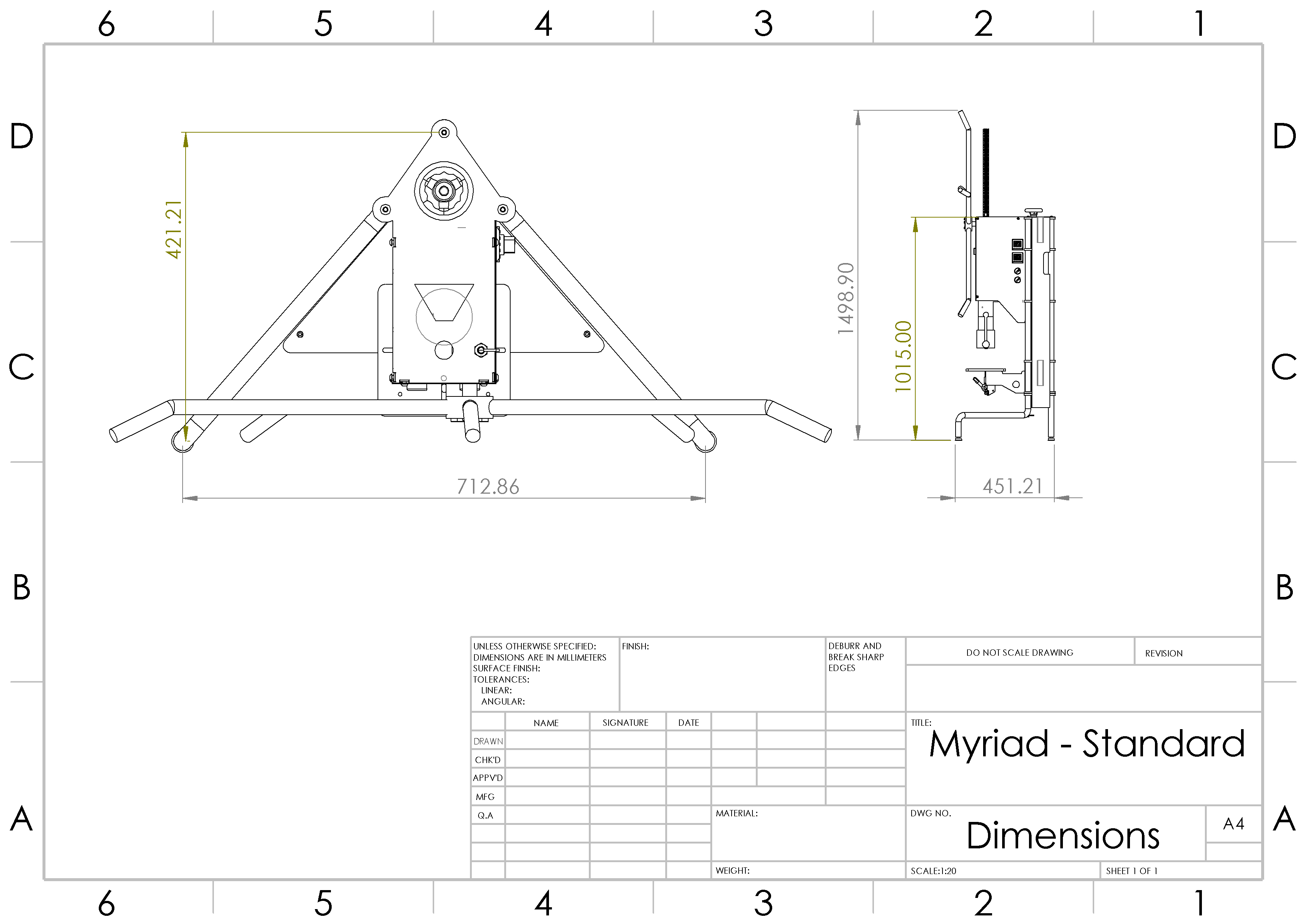

Dimensions

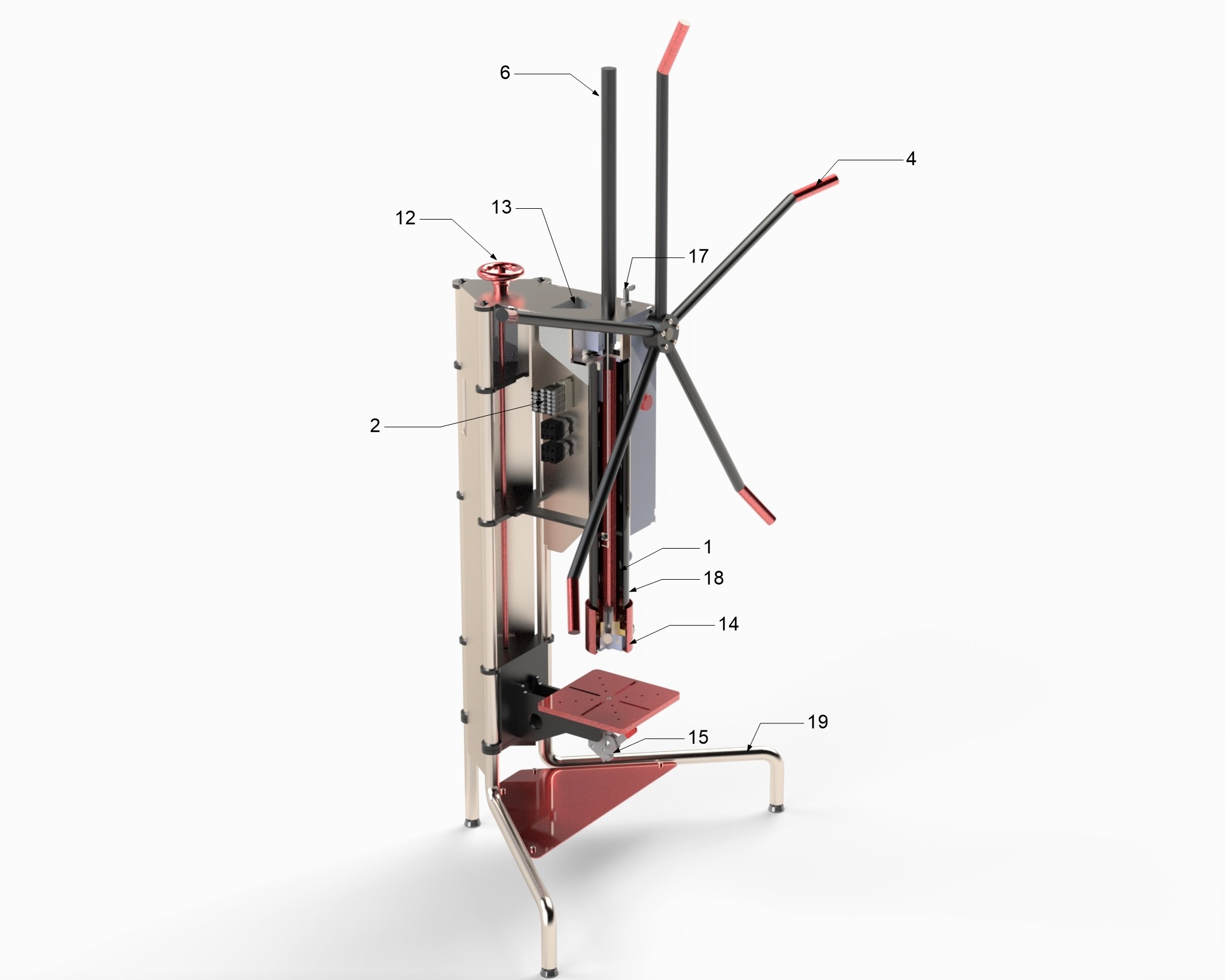

| Part Nr. | Description | Configuration |

|---|---|---|

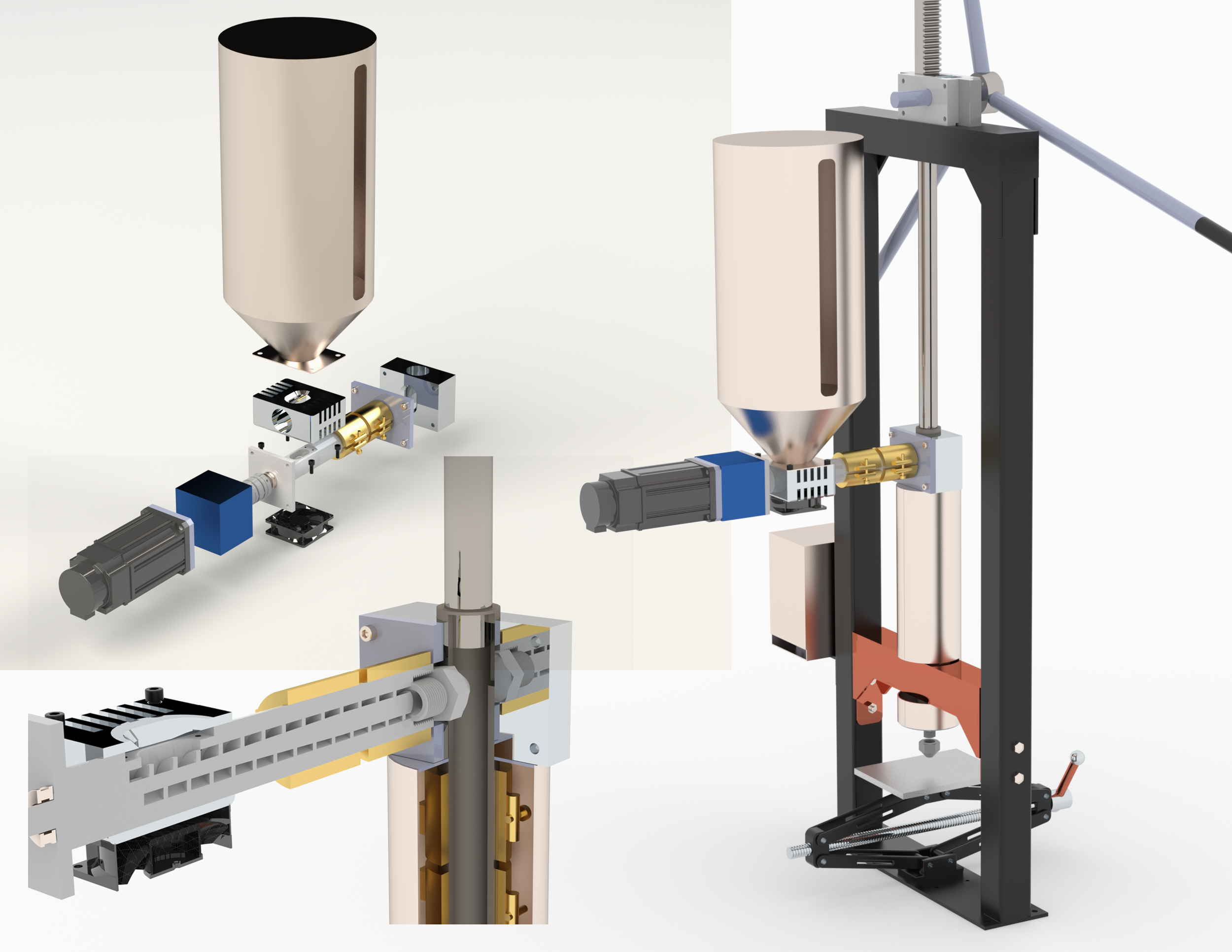

| 1 | Heatbands | 4x – 250W |

| 2 | PID Controller | InkBird 100-VH |

| 4 | Solid Round Bars | 5x – 25mm diameter / 50 cm long |

| 6 | Plunger | 25mm diameter / 38 cm long |

| 10 | Nozzle Interface | M20 / 12 mm bore |

| 11 | Nozzle | M20 / 12 mm bore with inset cone |

| 12 | Mold Height Adjustment | |

| 13 | Inlet | Stainless |

| 14 | Valve | Press cone or thread interface. See here for more. |

| 15 | Mold press lever | |

| 17 | Gear Lock | Spring loaded, prevents the plunger from going back |

| 18 | Heat insulation and shield | Wool and stainless |

| 19 | Framework | 25mm diameter tubes, stainless |

What others do with 'Myriad Injector'

Drawings

General Resources

Wiki Articles

- Precious Plastic - Bazar Guide

- PP Myth Busting

- Tips on making injection moulds

- Injection Moulding - Optimization & Speedup Tips

- Using the Injection machine

- Using the sheetpress

Comments